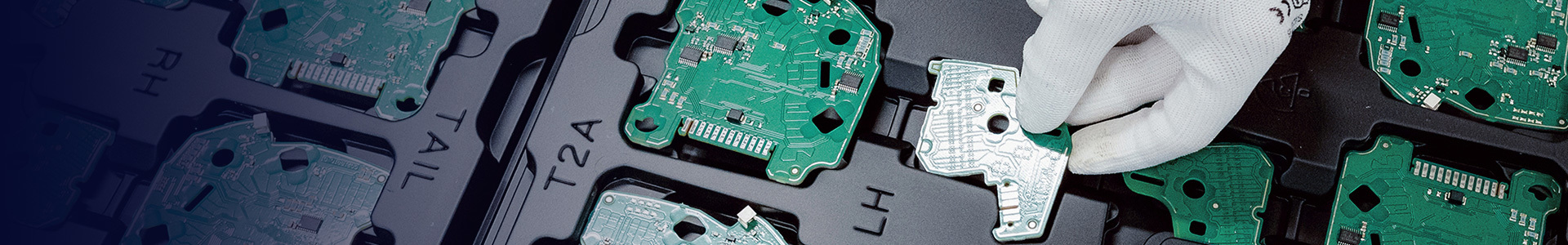

Professional Quality Assurance Team

Our quality assurance team consists of experts holding IPC Level 2 and Level 3 certificates. They have been subject to rigorous training and assessments, accumulating extensive practical experience.

We have comprehensive training facilities and implement ongoing skill enhancement programs along with comprehensive training evaluations to ensure that our quality assurance remains industry-leading.

Quality Management System Certification

New Project Quality Planning

Supporting customers' designs through DFM analysis, ensuring manufacturability from the start of design and reliable quality.

Aligning with customer requirements through technological disclosure sessions on product quality planning objectives and preliminary quality control schemes.

Customize new project planning paths to meet the needs of customers from different industries. Establish a quality gate and a traffic light system to oversee the new project planning.

Mass Production Quality Assurance

Raw Material Quality Control

Manufacturing Quality Management

Pre-Delivery Quality Inspection

After-Sales Quality Management

Systemic Quality Performance Monitoring System

Current State Analysis

Pilot Implementation

Digital Upgrade