Eolane R&D Solves PCBA Inspection Pain Points

Date:2023.12.27

Type: éolane News

In the increasingly competitive global Electronic Manufacturing Services (EMS) industry, Eolane china focuses on providing in-depth customized solutions to our customers. Our core competence lies in understanding the unique needs of our customers and developing innovative and efficient technical solutions that precisely address the complexities of the production line.

Eolane R&D team has demonstrated its innovative strength when faced with inspection problems that are difficult to solve with standard AOI. We are constantly exploring new technologies to improve the accuracy and efficiency of the inspection process through cooperation with machine vision component manufacturers, ensuring that production line problems can be quickly localized and efficiently solved.

Case 1

Lead inspection on an industrial module

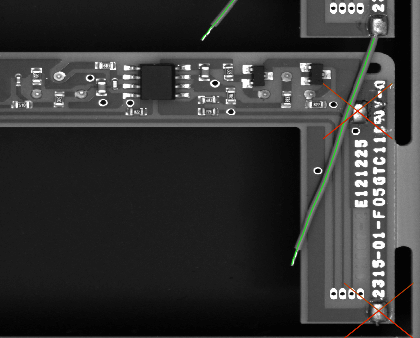

Problem: Cables and general components are different, easy to deform, prone to cross each other and overlap, etc. The original use of standard AOI equipment inspection, can only detect a section of the cable, can not detect the entire line, resulting in a lot of unqualified cables can not be detected.

Solution: In a short period of time to achieve the fitting of the entire cable, can accurately detect the length of the entire cable, the degree of bending, direction, etc., and is not subject to the influence of the cable overlap.

(There is no cable on the pad itself, but other cables pass right through the pad, which would be missed by standard AOI, but Oran's equipment can accurately detect the defects.)

Case 2

Connector tilt detection on an industrial module

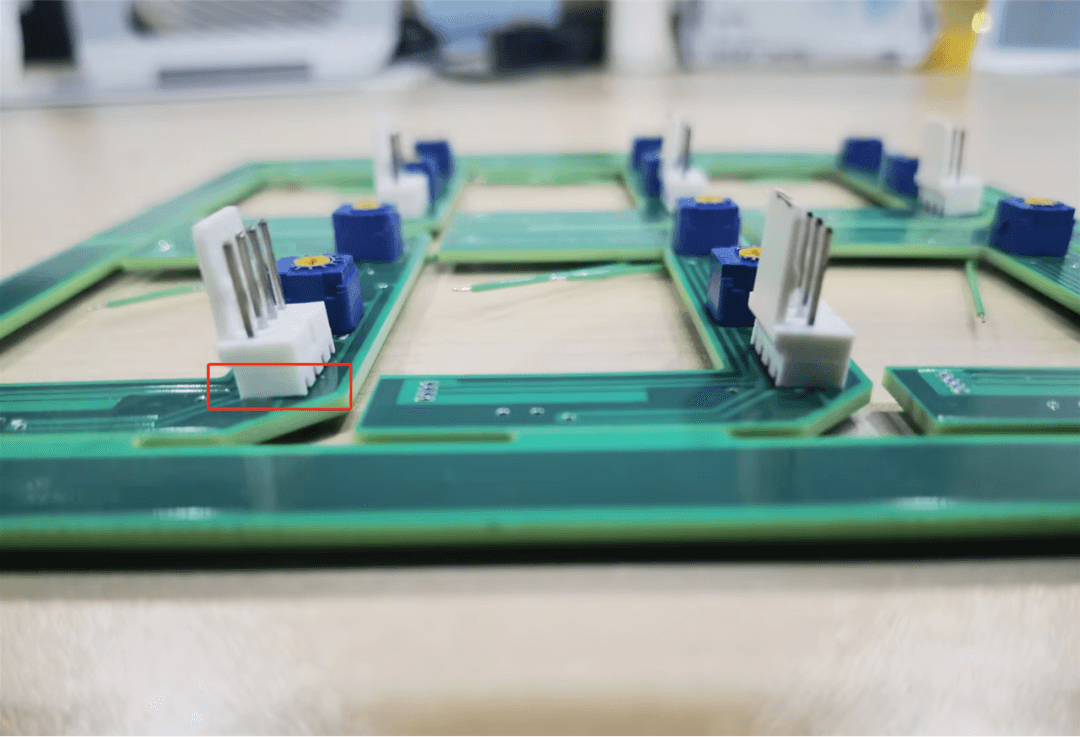

Problem: Mildly tilted connectors and normal connectors are almost indistinguishable from the front, and can only be recognized by looking carefully from the side, which is inefficiently detected manually and easily missed. Only 3D AOI in the standard equipment has the ability to detect such defects, but 3D AOI is expensive, and the detection time is long, it takes about 1 minute to complete the inspection of the whole board with 6 connectors.

Solution: the use of optical design, supplemented by machine vision technology, the problem connector fast judgment, only 0.1 seconds, you can complete the whole board 6 connectors detection, after the production line measured, error detection rate of 100%!

Case 3

An industrial module through-hole inspection

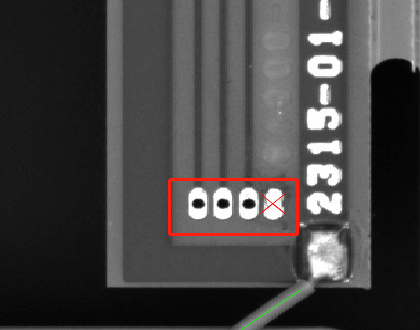

Problem: The perforation is easily blocked by solder in the production process, if the use of AOI equipment inspection is more cumbersome, inefficient and time-consuming, and if the reliability of manual inspection can not be guaranteed.

Solution: eolane independently developed equipment to successfully realize the inspection of over-hole, 48 over-hole inspection only takes 0.1 second.

Eolane is more than just a traditional EMS provider, we provide in-depth insight into each project, focusing on the development of customized solutions. By working closely with our customers, we are able to design and implement strategies specifically tailored to meet their specific challenges and goals, reflecting our commitment to customization, from basic board assembly to complete end-to-end supply chain solutions.