Automation

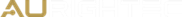

PCB Punching & Visual Inspection & Packing Line Case

This efficient, precise, and stable automated production line utilizes Omron NX serial controllers, Cognex visual inspection systems, Panasonic servo systems, and Datalogic barcode reading systems. It assures picking and placement accuracy of ±0.02 mm, with an output of up to 3000 units per hour, and fully automates the process from loading to packaging, securing stable production quality and maximizing output.

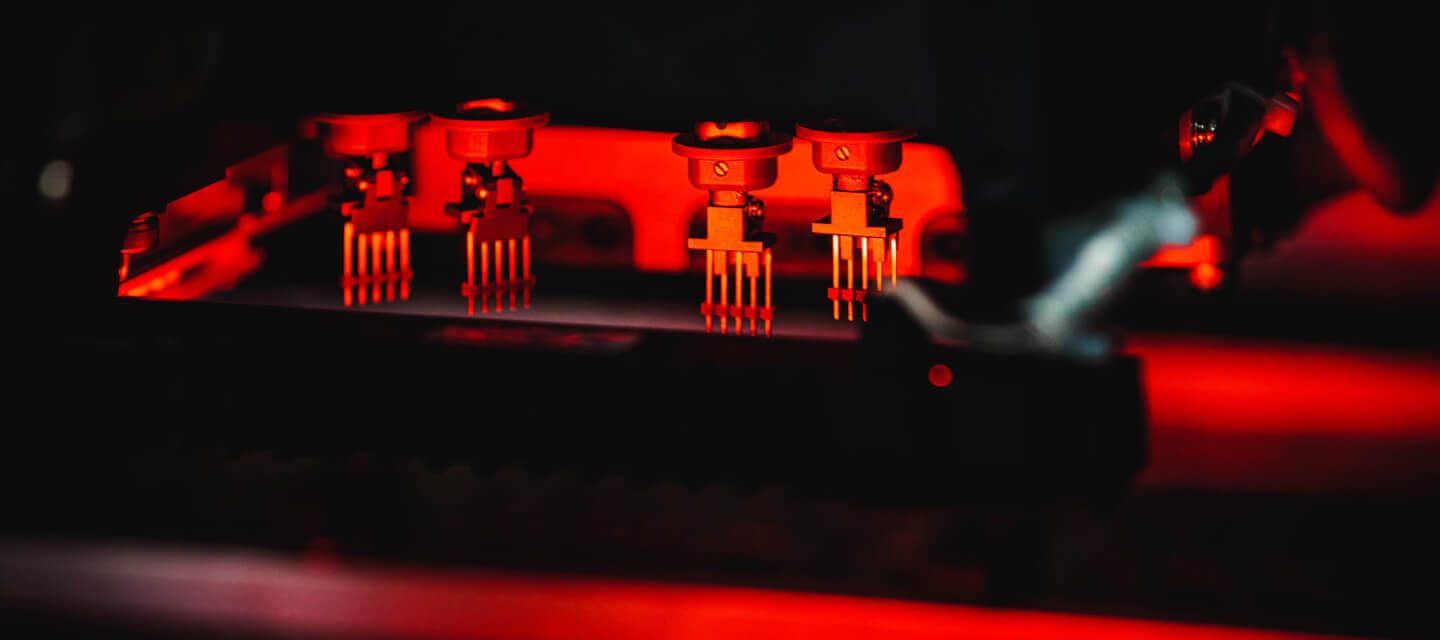

Automated Production Line Case

This line features automatic board loading, automatic routing, and automatic carrier return functions. With EPSON industrial robots and vision systems, PCBs are automatically placed into routing trays and then transferred to an inline routing machine for auto routing. After routing, products are automatically transferred to a particulate cleaning room for AOI inspection and sorting. Then, the qualified products undergo particulate cleaning. This line not only reduces manual operation time but also complies with customers' stringent cleanliness standards for their products.