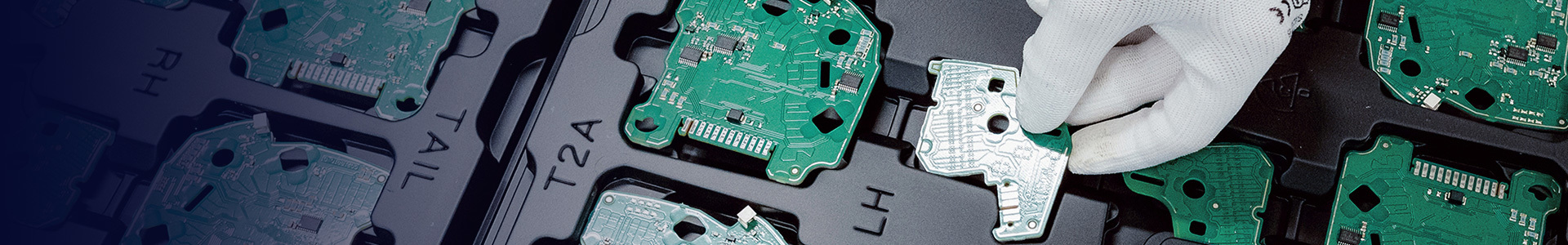

SMT

Surface Mount Technology (SMT) is a mature technology to install surface-mount components on the PCB surface and assemble them using the reflow soldering process.

SMT Line Configuration

Printer

SPI

Placer

Reflow oven

AOI

X-Ray

Process Capability

Our placement equipment comes with multiple modules and various types of mounting heads to adapt to the mounting requirements of components of all sizes, ranging from 0.2 mm × 0.1 mm to 74 mm × 74 mm. In addition, it can also be modularly expanded based on product characteristics and production needs to maximize manufacturing efficiency.

Process Precision

Our high-precision equipment can meet the printing and mounting requirements for chip components with a minimum spacing of 0.3 mm.

Precise process control ensures accurate placement and soldering of devices, ensuring product quality and reliability.

Process Efficiency

Our SMT lines operate at high speeds, reaching the mounting points of over 260,000 per hour.

The high mounting speed enhances manufacturing efficiency and shortens the manufacturing cycle, ensuring the timely delivery of high-quality products.

Quality Assurance

Through the use of Automated Optical Inspection (AOI) machine and X-Ray inspection machine, we implement comprehensive quality control to proactively identify and correct defects in the manufacturing process, ensuring excellent quality.

PCBA Back-End Manufacturing Processes

Backend

PTH

Wash cleaning

Conformal coating

Routing

Assembly

Function test

Packing

We provide high-quality PCBA back-end comprehensive manufacturing process services, with excellent process capability.

Eolane provides high-precision, environmentally friendly, and customized one-stop solutions for PTH production, ensuring product performance, durability, and safety.

PTH line configuration:

Auto-insertion

Wave/Selective wave

AOI

High-precision automated insertion and selective soldering capabilities.

Advanced cleaning processes and technologies.

Customized conformal coating solutions for improving product performance and durability.

Fast and precise de-panelization technology for various panel designs.

Mature application of assembly processes.

Reliable functional testing.

Customized packing solutions